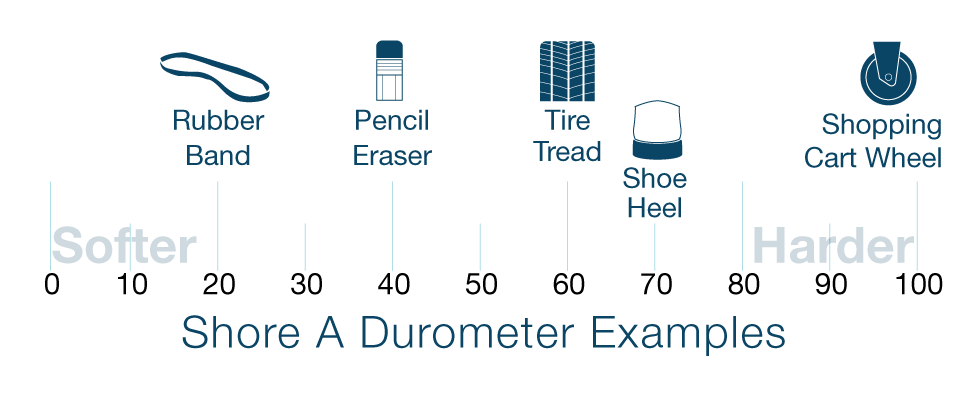

Durometer is a measure of how hard a material is. Technically, it’s a measure of how hard it is to permanently indent a material. There are actually 12 different durometer scales each measured from 0 (softest) to 100 (hardest), but for the we’ll mainly be talking about Shore A since it’s the most common in fluid sealing applications.

How is Durometer Measured?

Measuring durometer is fairly simple. You put a standard metal rod at a standard pressure on to a material for 15 seconds, then you measure the depth of the indentation. For example, in Shore A durometer testing, 1.1 to 1.4 mm diameter steel rod with is applied with .822 Kg of mass (1.81 lb) on a sheet of rubber for 15 seconds.

Which Durometer is right for your Project?

| Property | Low Durometer | High Durometer |

| Durability | Less Durable More easily marked |

More Durable Harder to mark |

| Compressibility | More Compressible | Less Compressible |

| Flexibility | More Flexible Better for curved surfaces |

Less Flexible |